You are here

RT-5 SP

The RT series are CNC lathes designed for high precision and for complex machining, up to 3 axis. They are compact machines specialized for micromechanics. They combine efficiency and versatility.

The RT-3's big brother. The RT-5 SP has extended travels with 200mm in X, 600mm in Z, 700mm in between centers and a bar capacity of 42mm.

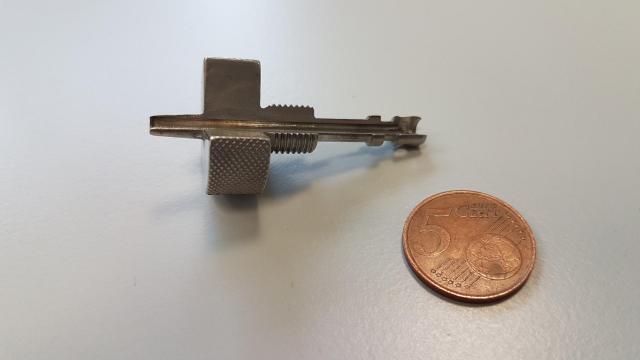

The RT-5 SP is a 2-axis toolmaker lathe with live-tooling option. It is used for machining medium and small parts. This a machine made for high-precision machining and hard turning.

For more than 30 years, the REALMECA machine beds have been made of a composite material with high density. This material guarantees improved vibration absorption, high stress resistance and thermal stability for :

- optimal surface finishing

- a long service life for cutting tools

- higher processing speeds

The connection elements for the spindle headstock and cross-slides are integrated directly into the machine base. The surface flatness, parallelity and squareness of these components within 2μm tolerances are achieved via hand scrapping. The extremely precise linear roller guideways are then mounted directly onto the almost perfect surfaces.

VDI30 turret

VDI30 turret Tailstock

Tailstock 9/12kW spindle motor

9/12kW spindle motor

| Capacity |

|

|

X axis |

200 mm |

|

Z axis |

585 mm |

| Between centers |

700 mm |

|

Tailstock |

CM4 |

|

C axis |

360° |

|

Spindle |

|

|

Max. speed |

5000 rpm |

|

Max. rating |

9/12 kW (15/21 kW option) |

|

Spindle nose |

Ø 110 mm |

|

Bar capacity |

42 mm |

|

Feedrates |

|

|

Max. cutting |

15m/min |

|

Rapids |

15m/min |

|

C axis |

300 rpm |

|

Precision |

0,1µ / 0,001° |

|

Turret |

|

|

Capacity VDI 30 |

12 |

|

Live tooling (option) |

|

|

Capacity VDI 20 |

12 |

|

Number of live-tool position |

6 |

|

Max. rpm |

6000 rpm |

|

Size / Mass |

|

|

Length / Width / Height |

2600 x 1750 x 1700 mm |

|

Weight |

3100 kg |