You are here

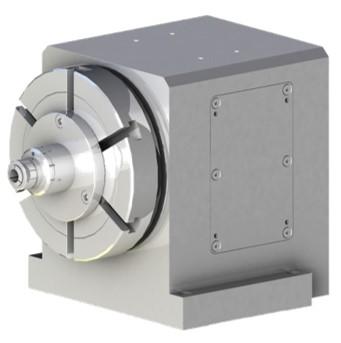

RV-3 SP

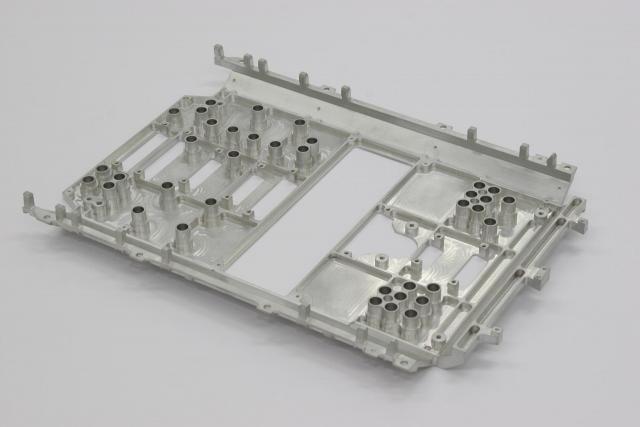

The RV range of machine has been especially developed for the production of high technicity parts in advanced technological sector like aerospace, medical, engraving, optical, electronic and many more in the micromechanics sectors.

The RV-3 SP offers extended travels with 350x240x305mm, bigger than the RV-2 SP.

It is a 3-axis milling center equiped with a vertical spindle. This machine is dedicated to micromechanics and notably the watchmaking and medical sectors.

Available in a 5-axis version.

For more than 30 years, the REALMECA machine beds have been made of a composite material with high density. This material guarantees improved vibration absorption, high stress resistance and thermal stability for :

- optimal surface finishing

- a long service life for cutting tools

- higher processing speeds

The connection elements for the spindle headstock and cross-slides are integrated directly into the machine base. The surface flatness, parallelity and squareness of these components within 2μm tolerances are achieved via hand scrapping. The extremely precise linear roller guideways are then mounted directly onto the almost perfect surfaces.

18 stations tool changer

18 stations tool changer Microlubrication

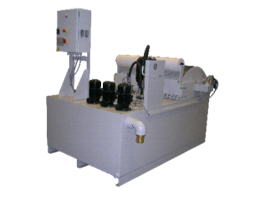

Microlubrication Electrostatic filtration

Electrostatic filtration Oil filtration

Oil filtration

|

Capacity |

|

|

X axis |

350 mm |

|

Y axis |

240 mm |

|

Z axis |

300 mm |

|

Spindle |

|

|

HF80 |

|

| Max. speed |

50 000 rpm |

| Max. rating |

2,5 kW / 3,2 kW |

|

Taper |

HSK-E25 |

|

HT80 (option) |

|

| Max. speed |

30 000 rpm |

| Max. rating |

3,3 kW / 4,3 kW |

|

Taper |

HSK-E25 |

|

HF120 (option) |

|

| Max. speed |

42 000 rpm |

| Max. rating |

13,8 kW /19,6 kW |

|

Taper |

HSK-E40 |

|

Feedrates |

|

| Max. cutting |

30 m/min |

|

Rapids |

30 m/min |

|

Precision |

0,1µ |

|

Tool changer |

|

|

Number of station |

18 - 30 - 60 (HSK25) |

|

Size / Mass |

|

|

Length / Width / Height |

2350 x 1670 x 2150 mm |

|

Weight |

2900 kg |