You are here

The company

REALMECA is a French company located in Clermont-en-Argonne (55), FRANCE. It has two main activities:

- An aeronautical division machining complex technological components for the most important European aeronautic companies.

-

A machine tool division specialized in developing, manufacturing and exporting across the world:

- High precision lathes;

- High precision and high-speed mills;

- Multifunction machines of hyper precision using high-frequency spindle

With more than 6 000 machine tools sold across the world, REALMECA provides manufacturing workshops of the largest international brands in several sectors like medical, jewellery, optical, micromechanics, electronics, aerospace, and automobile.

REALMECA particularly focuses on:

- Meeting the needs of customers for the machining of mechanical components;

- Offering efficient and complete machining solutions;

- Supporting the customer in the realization of its project and the training of its staff;

Skills and expertise:

Aside from manufacturing its own range of machine tools, REALMECA produces technical parts for our aeronautical division using these same machines. Thanks to that, our staff has become increasingly skilled in several domains:

- Milling,

- Micro milling,

- Machining (laser and HSM),

- Turning,

- Grinding,

- Automation,

- Development of complete technical solutions,

Sectors of activity:

Thanks to our level of expertise, REALMECA's machine-tools are being used in different sectors, such as:

- Watchmaking

- Jewellery

- Optical

- Medical

- Micromechanics

- Electronics

- Aerospace and aeronautics

- Automobile

A complete vision

REALMECA offers a range of "tailored" machine-tools that meet the requirement of high technology sectors such as micro-mechanics, medical applications, watchmaking, automotive engineering, aeronautics, electronics... all fields that face the need for ultra-precision manufacturing.

- Designing:

REALMECA's design office is in charge of creating the machine that will fit the most to your activity, based on one our existing models of lathe, mill, or multifunction machine.

Our engineers and experienced technicians will work with you to design the machine that will meet all of your requirements, as they stay in contact with you at every steps of its conception.

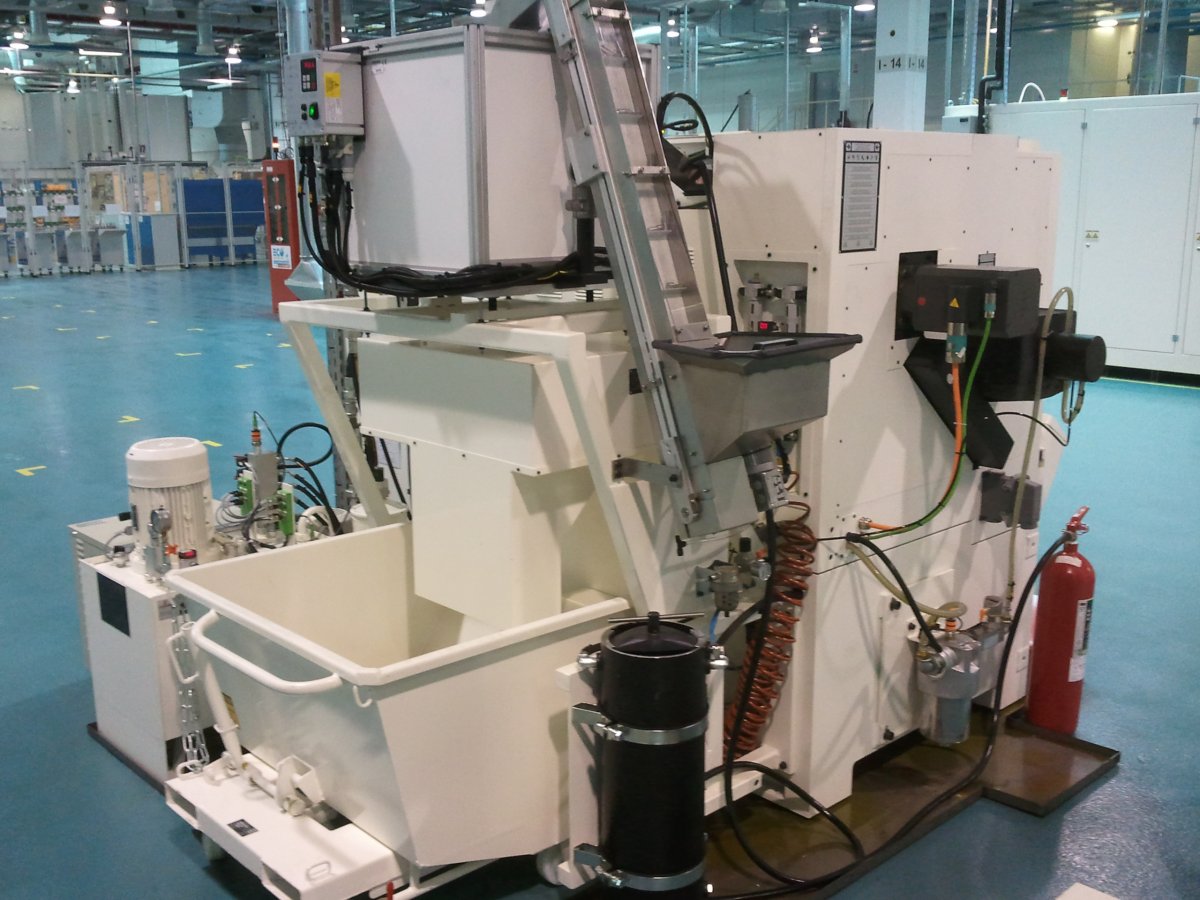

- Building:

Once the design of your machine has been finalized, it will be manufactured and put together directly inside our workshop. This includes: manufacturing the base, installing and painting the metal casings, and obviously connecting all the electronic parts that make the machine functional. All of this is realized by our experts.

- Testing:

Once your machine has been fully assembled, a series of tests is realized to verify and ensure the quality and precision of your machine.

- Training:

REALMECA provides training for operators and maintenance personnel. Numerous technicians and engineers, including more than 4500 teachers, have been trained in the use of new technologies (CNC, high and very high-speed machining, turning and milling of hard materials). The quality of the work and the efficiency of a machine depend on the way its operator uses it. For this reason, REALMECA has set up a training program tailored to your needs, led by experienced instructors.

- Supporting:

REALMECA provides support and monitoring of the process on the final site in partnership with your production and maintenance teams.

Tailor-made applications

Every new part manufactured needs a specific approach. The technical analysis of the process and the materials used, lead to specific technological choices. REALMECA extends the services of its own specialist engineering department to its customers, providing case by case recommendations to achieve the highest performance solutions. The expertise gained from more than 50 years of innovation means that Realmeca is able to provide a wealth of advice based on using the most advanced technologies.

Automation

REALMECA is able to provide a full set of automation solutions, tailored to your needs and matching the requirements of your activity

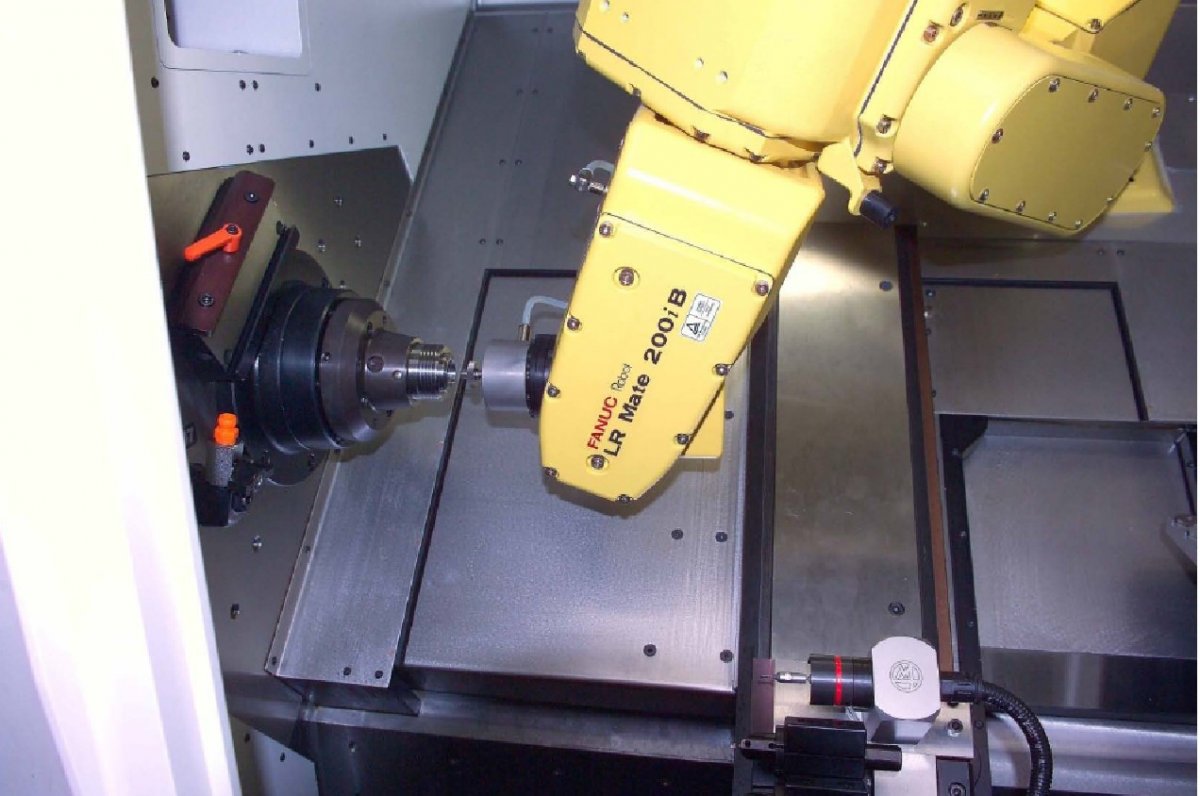

- Robot integration

The robot arm, directly connected to the machine, facilitates your production by manipulating the raw materials and the finished parts in and out of the machine without any intervention by the operator.

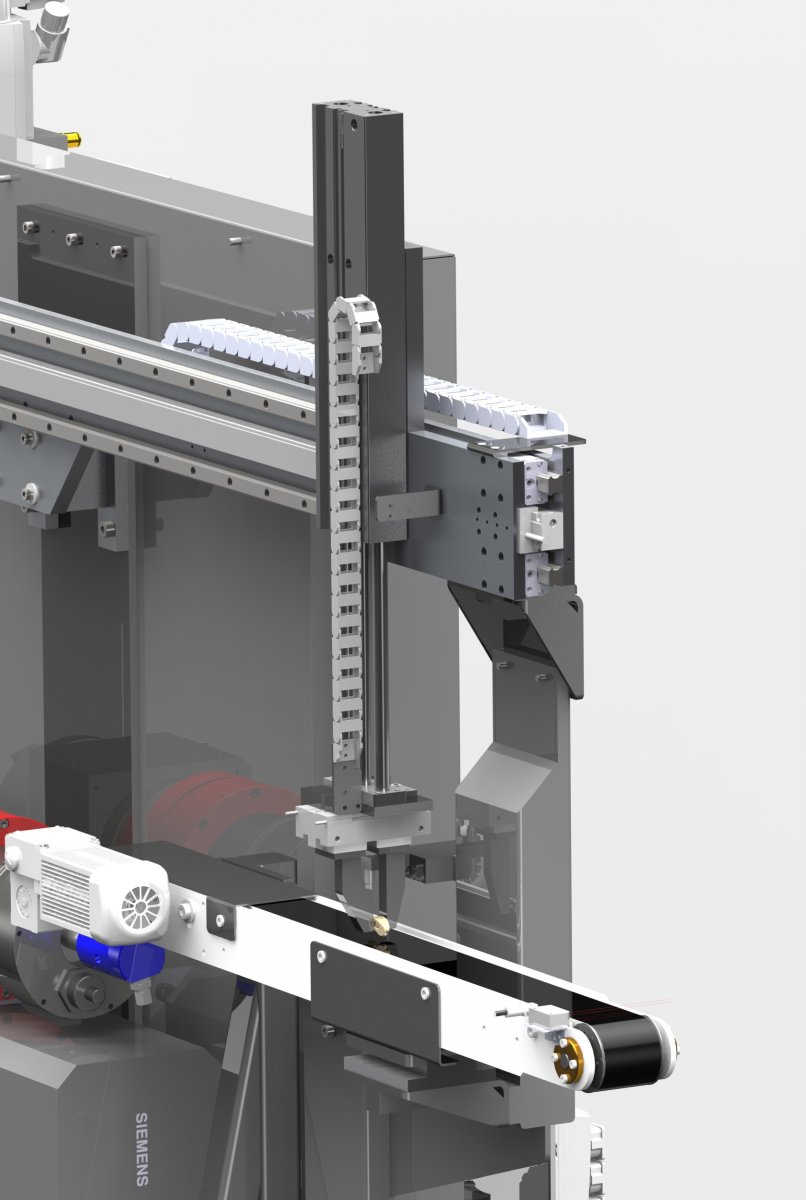

- Palletized system

A palletized system allows you to configurate in advance a complete production sequence, even with the production of different parts. The raw parts are installed on a pallet where they will be worked on one by one. The finalized parts can then be picked up from the pallet pool.

- Flexible cell

REALMECA can offer you to integrate a pallet automation system to your machine.

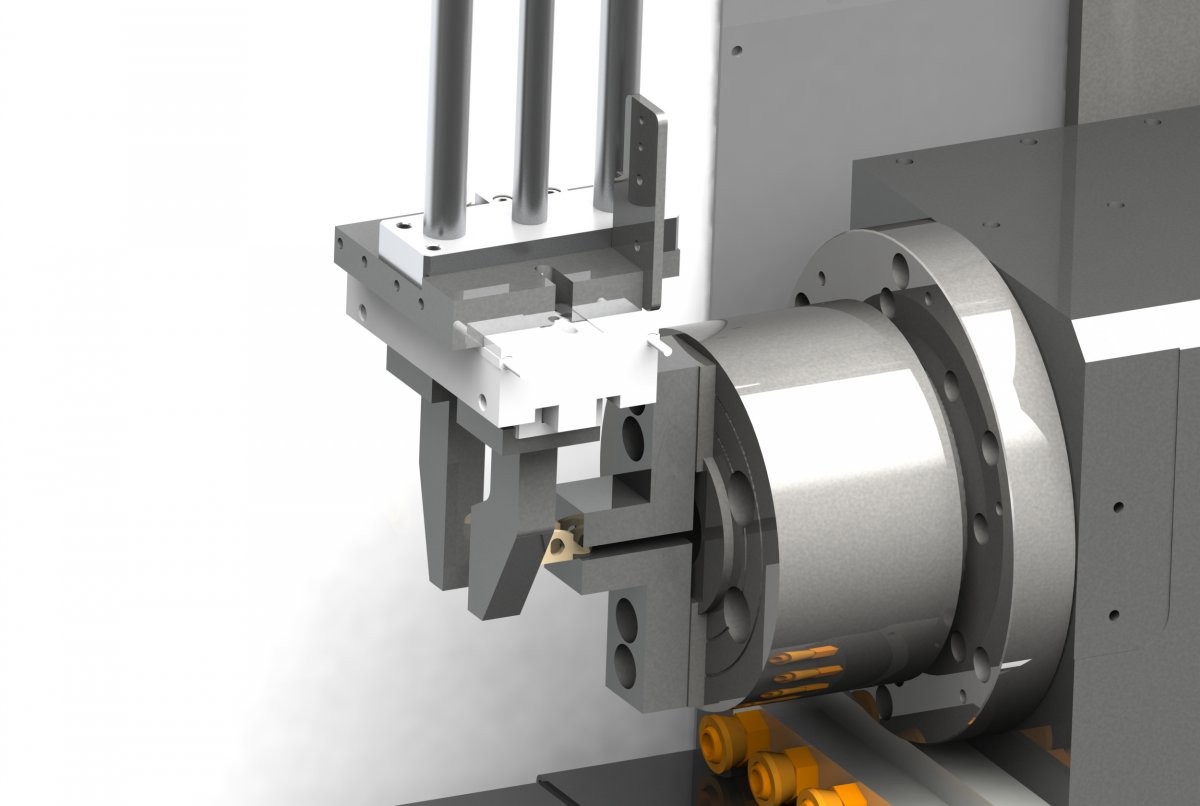

- Workpiece manipulation

This system is directly integrated to the machine. It uses a mechanical claw to pick up the finalized parts and remove them from the work area through a conveyor belt or treadmill.

- Bar feeder

REALMECA's lathes are compatible with bar feeders. Constantly supplying the machine with material, they allow the mass production of parts without any interruption.

- Vibrating bowl feeding

This automation system allows a constant supply of material to the machine.

Process monitoring and self-adjustment

The measuring instruments integrated to the machine allow a permanent monitoring of the quality of your parts and an optimization of your production.

History

REALMECA from 1962 to today:

- Founded in 1962 by Mr Jean Friess in Clermont-en-Argonne (France), the company's purpose was to design and produce automated threading lathes.

- In 1984, the smallest machining center on the market is launched: the C 250 V

- In 1992, REALMECA design the first French high-speed machining centers, starting with the C 400 UGV

- In 1999, REALMECA announces its partnership with the German company SPINNER, constructor of high precision CNC machines. Visit Spinner.eu.com

- In 2001, a range of multifunction machine-tools is created.

- In 2002, REALMECA extends its partnership with US company HAAS AUTOMATION, becoming the Haas Factory Outlet North-East France, official distributor of the HAAS machine-tools in France. Visit HaasCNC.com

- Youngest of the family, the REALMECA RM3-7 is launched in 2012.

- In 2018, the RV-2 and RV-3 are redesigned and modernised.

- Even today, REALMECA continues to maintain and update all of its machine to the latest technologies. Thus, being able to provide modern solutions to its customers.

- Since 1964, more than 6000 machines have been installed across the world.