You are here

RM-3 7

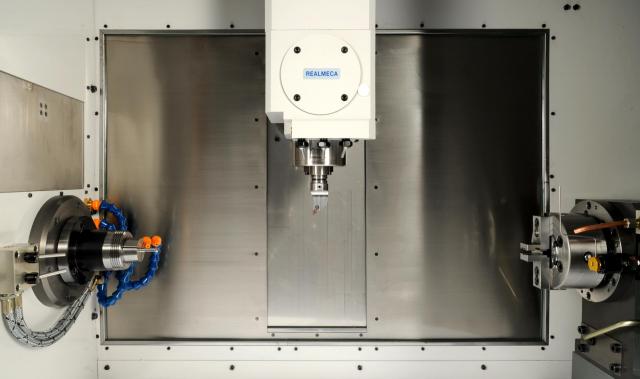

REALMECA's modular machines are multifunction machines combining turning, milling and grinding. They simplify your workflow by gathering all types of machining in a single machine, while maintaining the precision and rigor required for micromechanics.

The RM-3 7 is among the most advanced of REALMECA's machines. This multifonction machine allows machining on 7 axis while maintaining exceptionnal precision and repeatability.

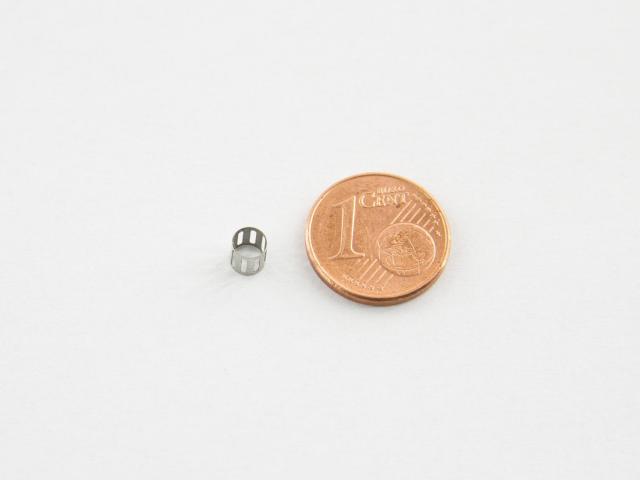

The RM-3 7 is a machine dedicated to micromechanics. Particularly the medical, optical, aeronautic and aerospace sectors thanks to its ability to create complex parts with flawless precision.

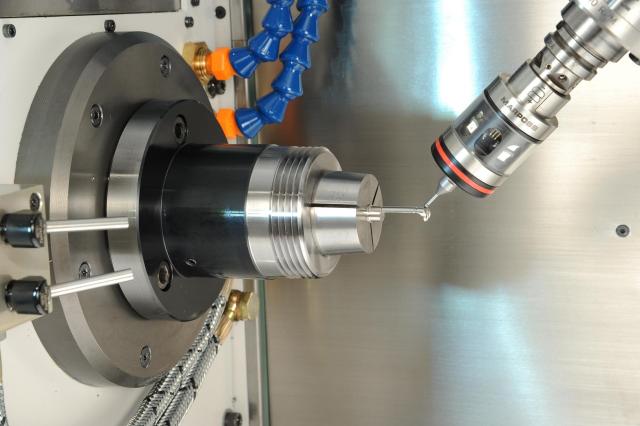

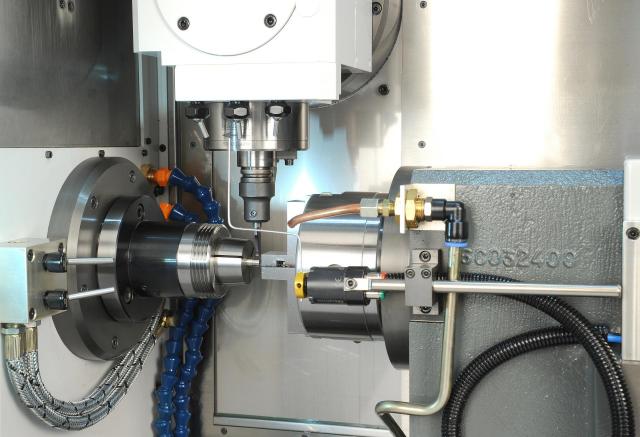

This is a milling-turning center equiped with 1 milling spindle and 2 turning spindles. It is able to machine a part on all of its different sides and, doing so, greatly reduce the time needed to obtain a finished part. It is capable of machining complex parts with great precision. It can operate on precious material like gold, as its design allows to filter and easily gather the chips.

For more than 30 years, the REALMECA machine beds have been made of a composite material with high density. This material guarantees improved vibration absorption, high stress resistance and thermal stability for :

- optimal surface finishing

- a long service life for cutting tools

- higher processing speeds

The connection elements for the spindle headstock and cross-slides are integrated directly into the machine base. The surface flatness, parallelity and squareness of these components within 2μm tolerances are achieved via hand scrapping. The extremely precise linear roller guideways are then mounted directly onto the almost perfect surfaces.

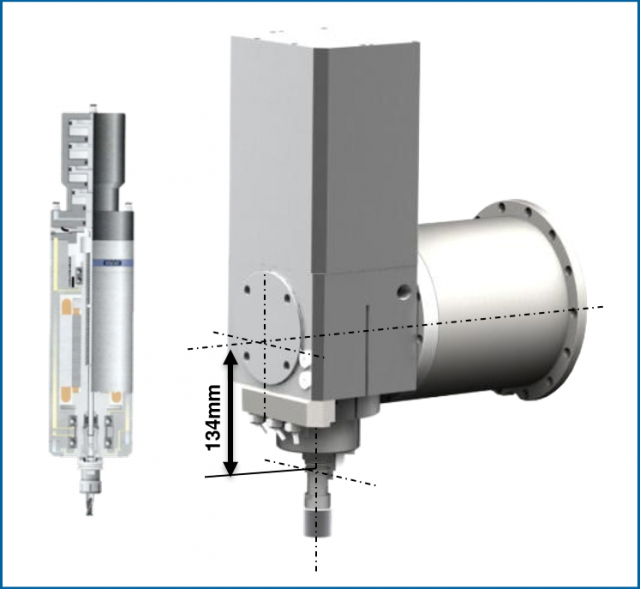

High speed milling spindle

High speed milling spindle Main turning spindle

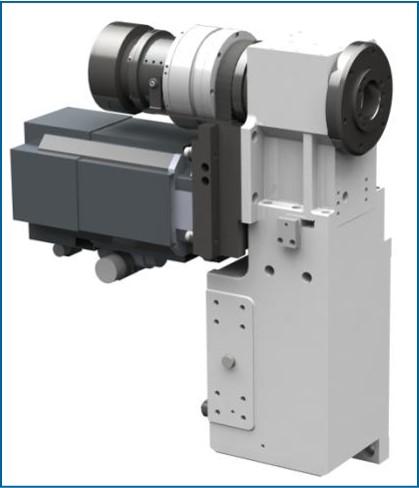

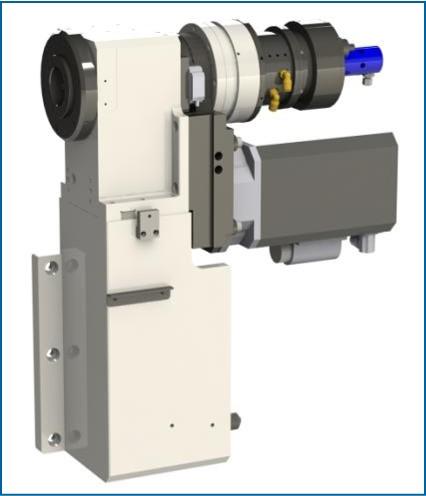

Main turning spindle Secondary turning spindle

Secondary turning spindle 60 stations toolchanger

60 stations toolchanger Part catcher

Part catcher Oil filtration

Oil filtration Electrostatic filtration

Electrostatic filtration|

Capacity |

|

|

Z1 axis |

580 mm |

|

Z2 axis |

585 mm |

|

Y axis |

140 mm |

|

X axis |

285 mm |

|

B axis |

100°/10° |

|

C1-C2 axis |

360° |

|

High-Speed Milling Spindle |

|

|

HF80 |

|

|

Max. speed |

50 000 rpm |

|

Max. rating |

2,5 kW / 3,2 kW |

|

Taper |

HSK-E25 |

|

HT80 (option) |

|

|

Max. speed |

30 000 rpm |

|

Max. rating |

3,3 kW / 4,3 kW |

|

Taper |

HSK-E25 |

|

Turning spindle 1 |

|

|

Max. speed |

6000 rpm |

|

Max. rating |

3,7 kW |

|

Spindle nose |

Ø 90 mm |

|

Bar capacity |

32 mm |

|

Bar capacity (option) |

42 mm |

|

Turning spindle 2 |

|

|

Max. speed |

6000 rpm |

|

Max. rating |

3,7 kW |

|

Spindle nose |

Ø 90 mm |

|

Feedrates |

|

|

Max. cutting |

30 m/mn |

|

Rapids |

30 m/mn |

|

B axis |

35 rpm |

|

C1-C2 axis |

100 rpm |

|

Precision |

0,1µ / 0,001° |

|

Tool Changer |

|

|

Number of station |

60 |

|

Size / Mass |

|

| Length / Width / Height |

2200 x 2150 x 2000 mm |

|

Weight |

3500 kg |