You are here

Case #4 : The french machine tools that watchmakers need

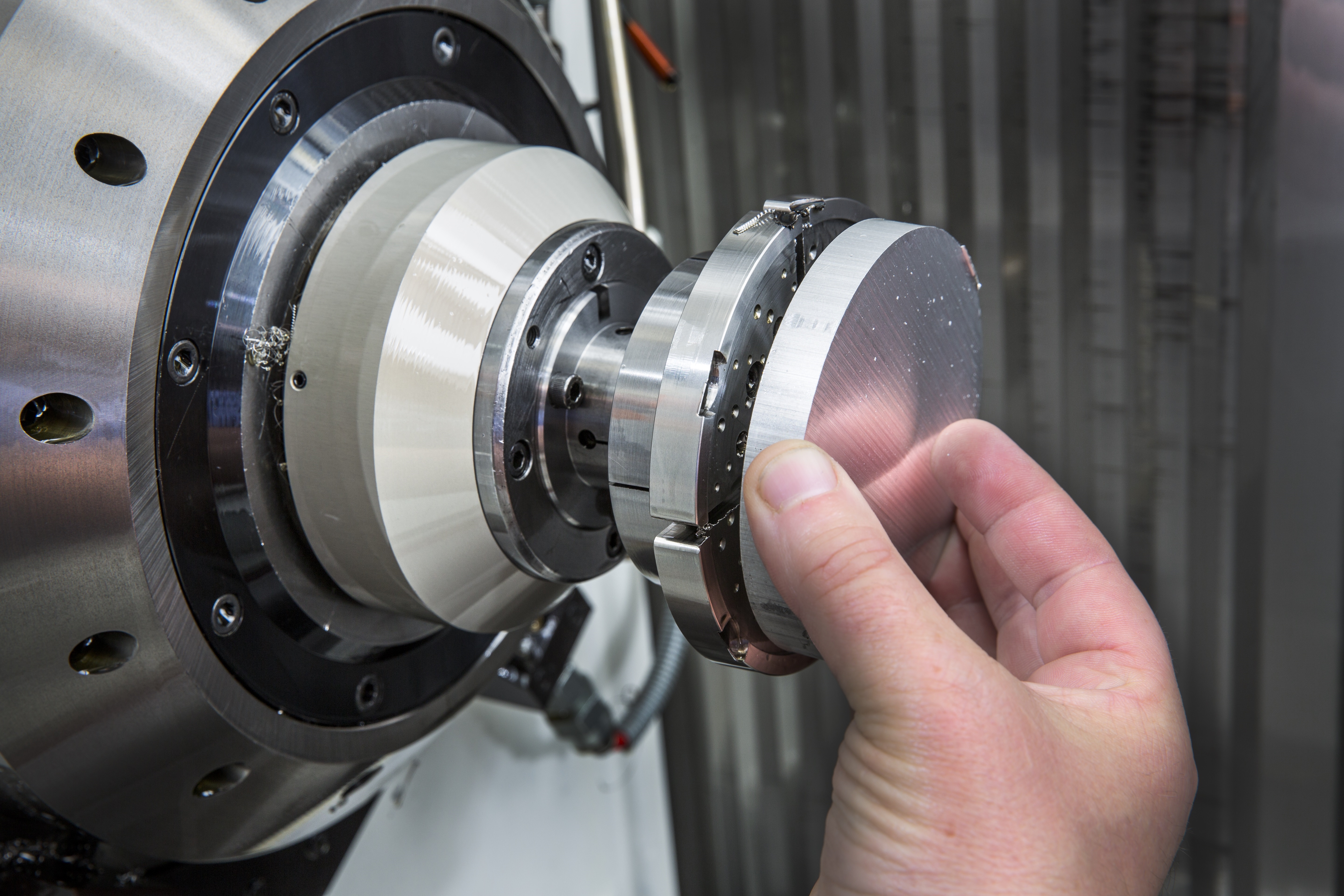

REALMECA was selected by a french manufacturer of luxury watches : B.R.M Chronographes. Manufacturing in the watchmaking sector requires an impeccable precision and good technical expertise to be able to work with high quality materials. The machines made by REALMECA can handle this kind of work, that is why they were a perfect fit for this french watchmaker.

Process(es) realised :

- Milling

- Turning

- Machining in one take

- "Mitraillage"

- Machining of titanium, carbon, Fortal HR®/AU4G…

Machine(s) used :

-

5-axis machining center RV-2 5A SP

- CN HEIDENHAIN 426

- Axis : X : 250mm, Y : 250mm , Z : 250mm

- 40 000 rpm spindle, HSK25, 3,4kW

- Laser tool measurement system

-

5-axis machining center RM5 H

- CN HEIDENHAIN 426

- Axis : X : 300mm, Y : 200mm, Z : 250mm

- Pallet 250 x 250 mm

- 24 positions tool-changer

- Oil skimmer

- 24 000 rpm spindle HF 100 A 45, HSK E 32

- Laser tool measurement system

B.R.M Chronographes arrived on the luxury watchmaker market in the year 2000's and they chose REALMECA's machines for the precise machining of their automatic watches components.

The watchmaker sector use materials that can be difficult to work with like titanium, ARCAP or maraging steel. The quality ratings for this sector are also more demanding, the closest to perfection, they are so that these luxury products can last in time.

The machines made by REALMECA perfectly met the needs of this sector and now, the french manufacturer has 30 000 made-in-France watches on the market. For them, our machines produce several parts, such as :

- Winding crowns

- Cases

- Main plates

- Balance wheels

- and many others...

Conclusion

With micron-scale precision, French REALMECA machines are the ideal candidate for the production of components in sectors where meticulousness and repeatability are required.

Access to the official BRM Chronographes website