You are here

Case #3 : Ultrasonic machining

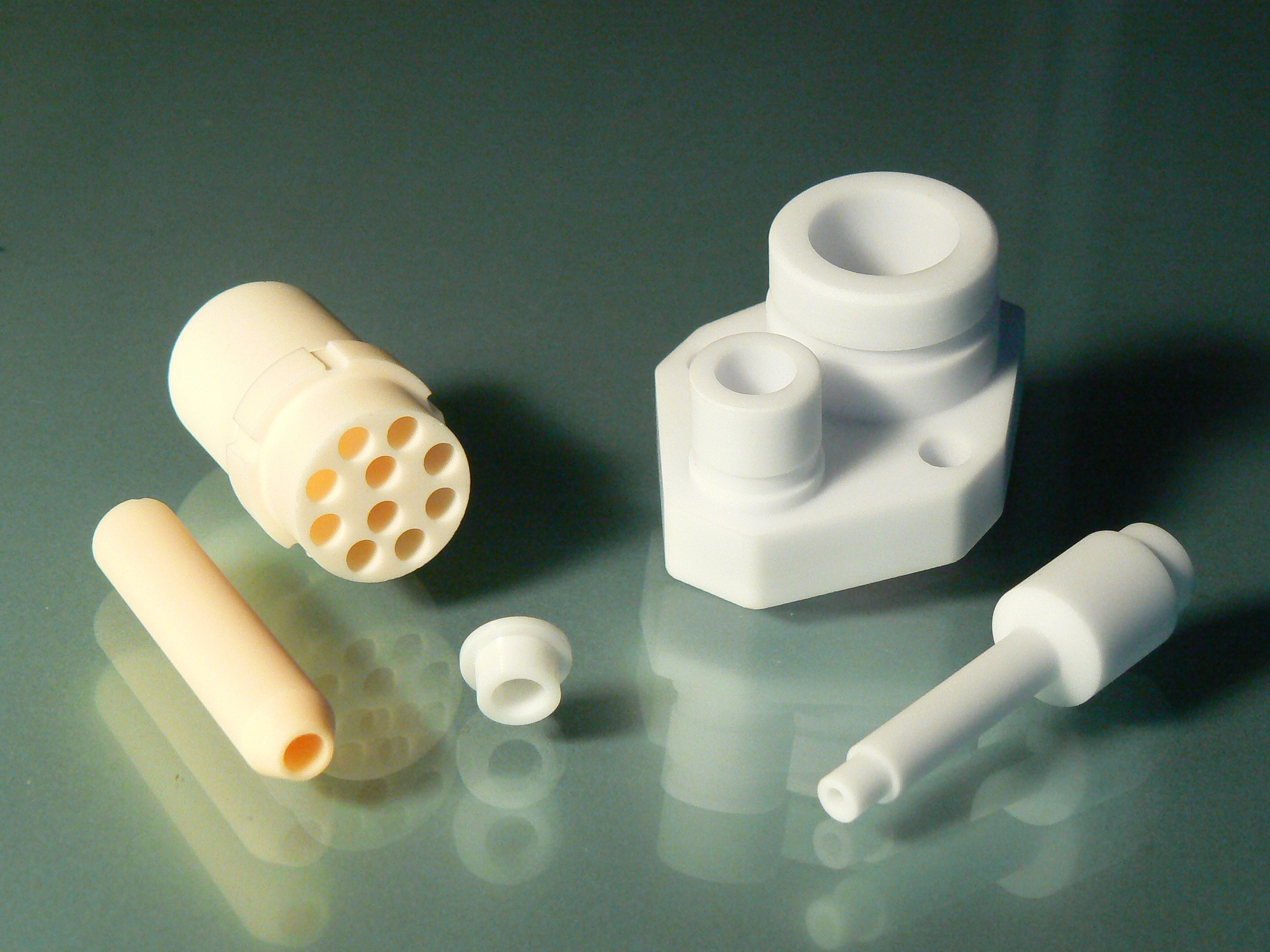

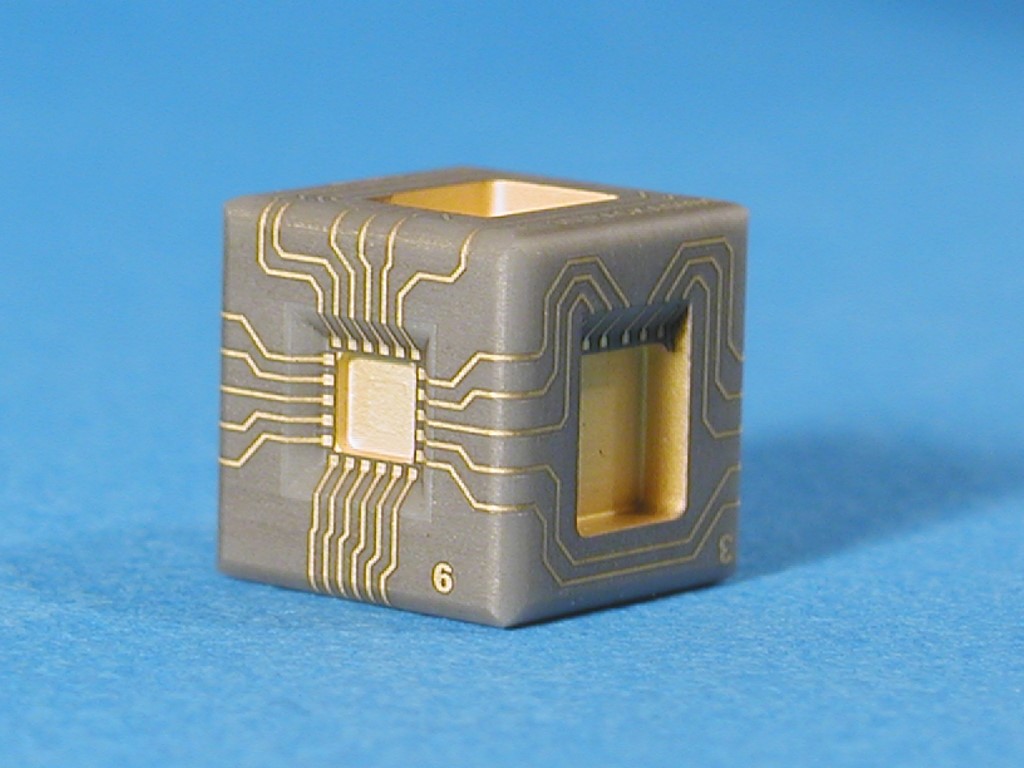

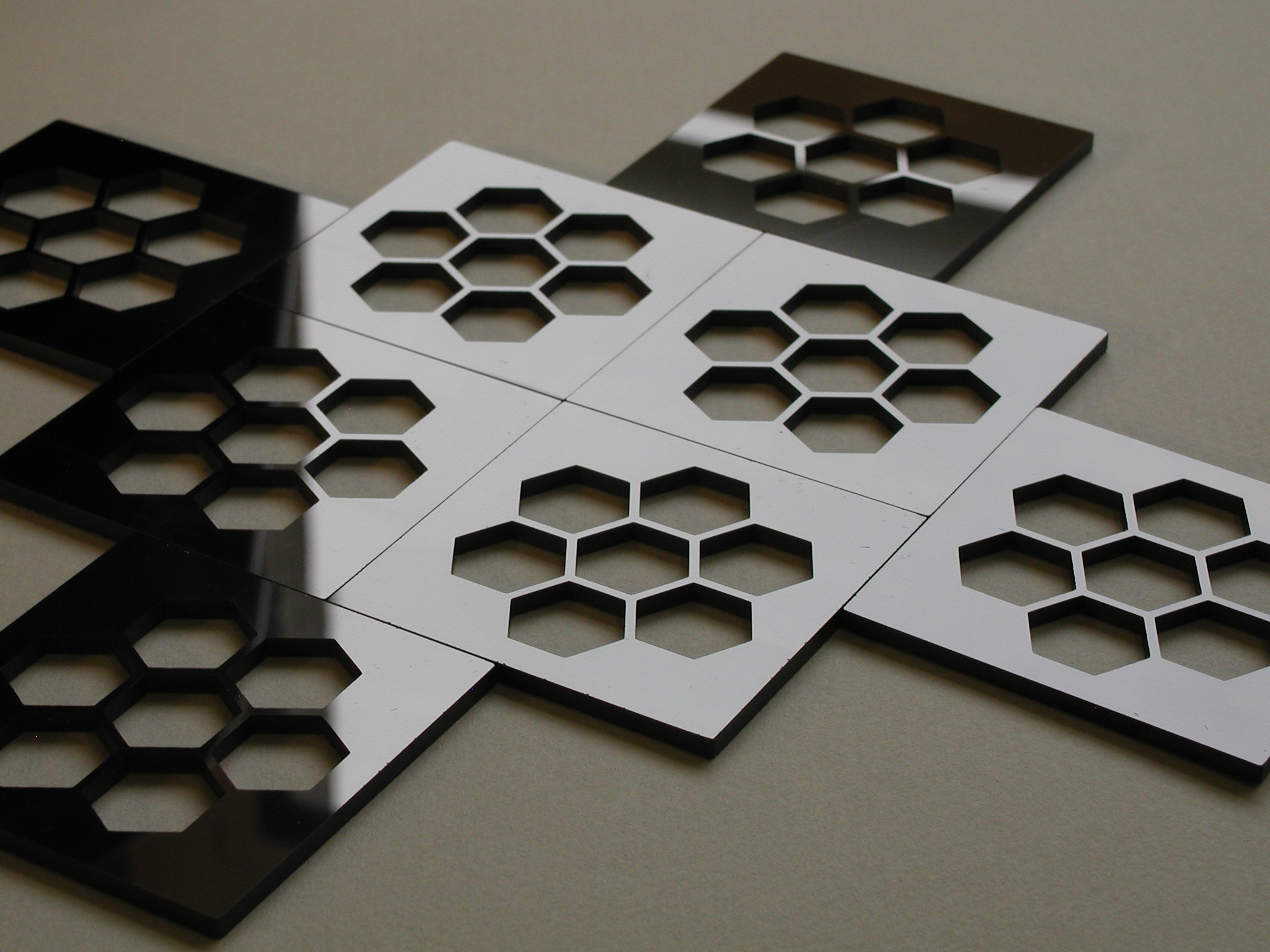

REALMECA worked with two other companies to put together this project : the creation of an ultrasonic machining center. This machine's goal is to manufacture complex parts in hard materials where a more classic machine would not reach the standards of quality and precision.

Process(es) realised :

- Ultrasonic machining

- Machining ceramic and hard materials

- Machining complex parts with high precision

Machine(s) used :

-

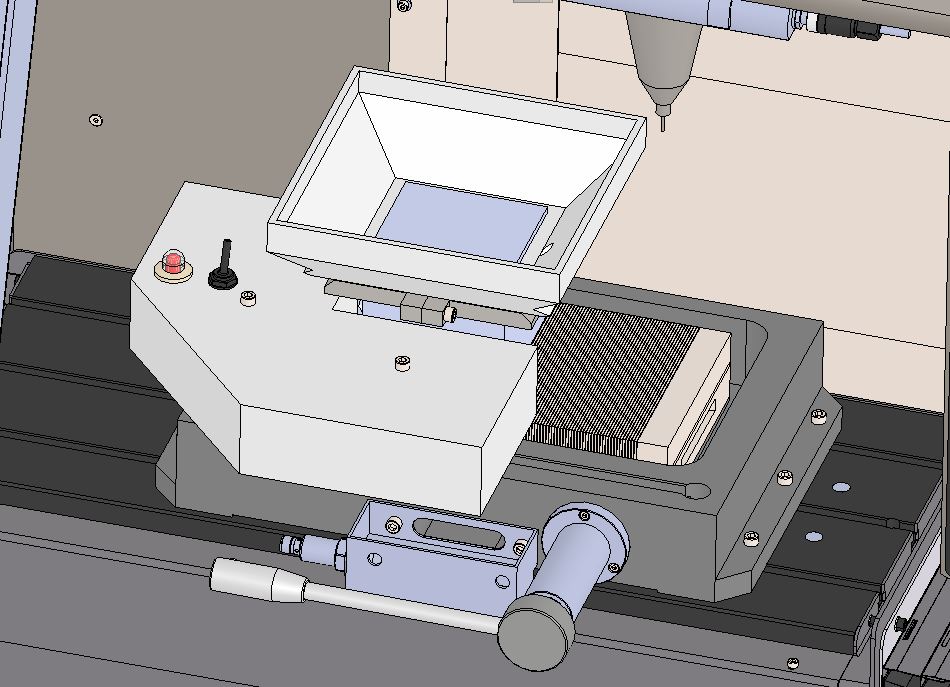

High speed vertical mill RV-3 SP UltraSonic

- CN HEIDENHAIN TNC 620

- Work table 660 x 280 mm

- Precision scales

- Sonotrode

- Sonotrode support

- Magnetic tray

- Secondary 15" screen

- Abrasive liquide pump

- Remote handle

REALMECA has been building machine-tools since 1962. Up to now, the machines made by REALMECA work by removal of material from a brut, using a spindle with tools for turning, drilling, milling, etc...

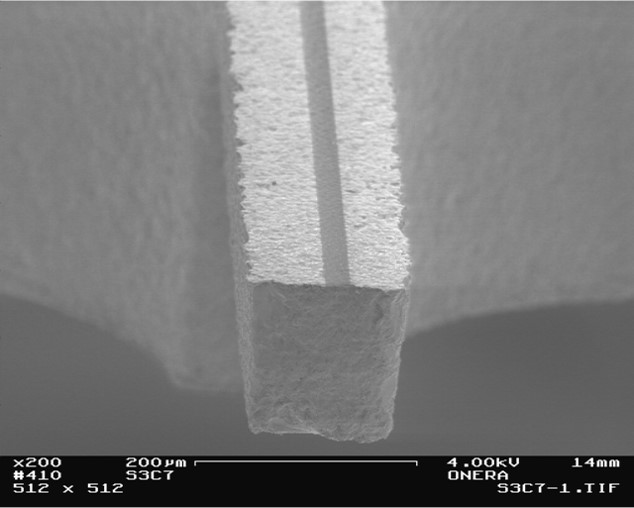

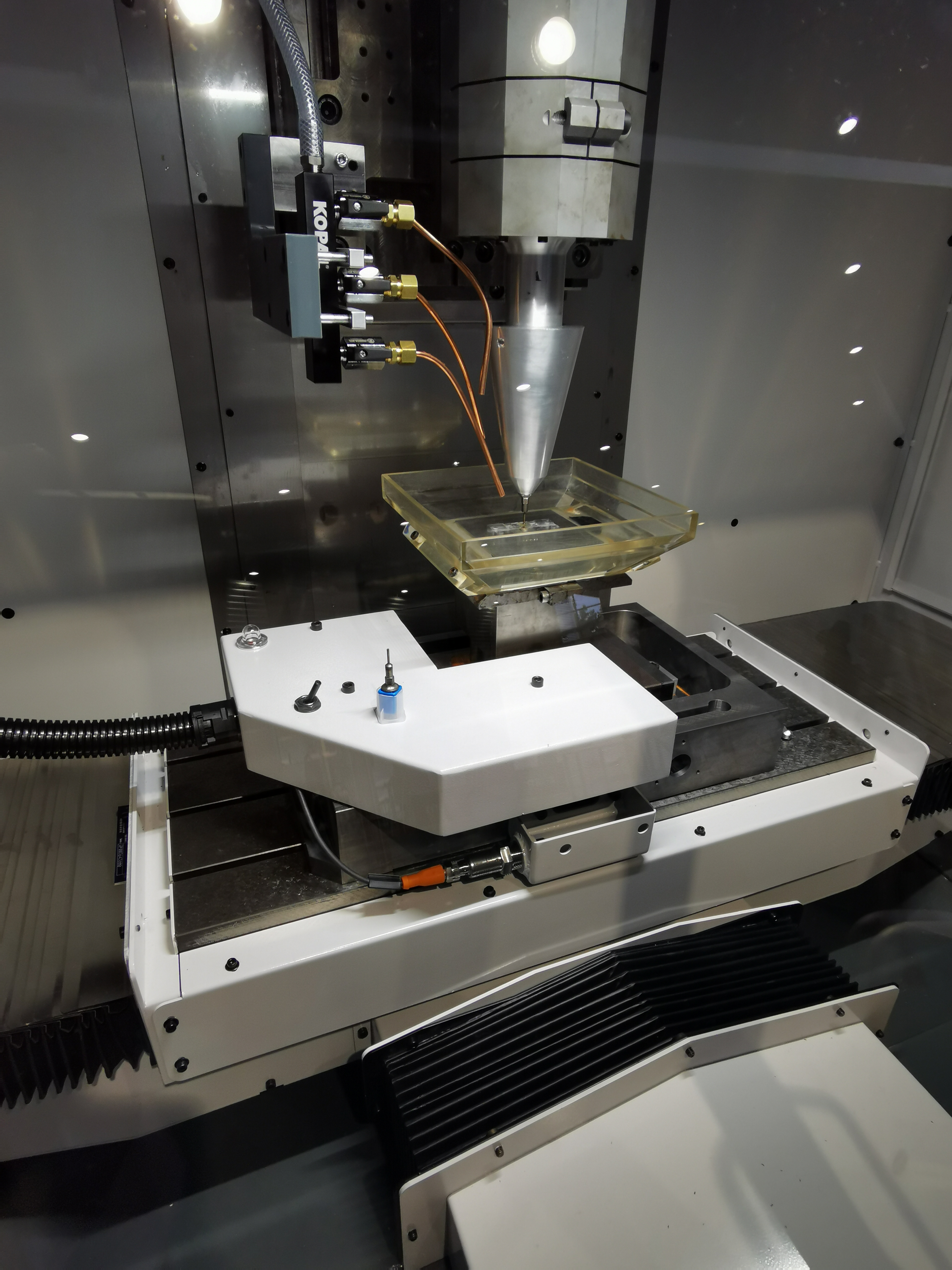

The goal of the RV-3 ULTRASONIC is to get away from this classic method of machining to allow the manufacture of hard material. Instead of a high-speed spindle, this RV-3 is equipped with a sonotrode. This sonotrode sends out vibrations at an ultrasonic frequency.

The tool mounted on the nose of the sonotrode will vibrate at high frequency and send out an abrasive solutions on the part and, doing so, erode it. This method of abrasive machining do not bring any constraint to the part and keep it from being damaged. This allow us to work more efficently on hard materials like ceramics, glass or quartz. The shape of the tool also allows the realization of rectangular pockets, sharp edges and to avoid any type of connection fillet related to any tool radius.

Creating this machine was a project that required many changes to our classic RV-3 :

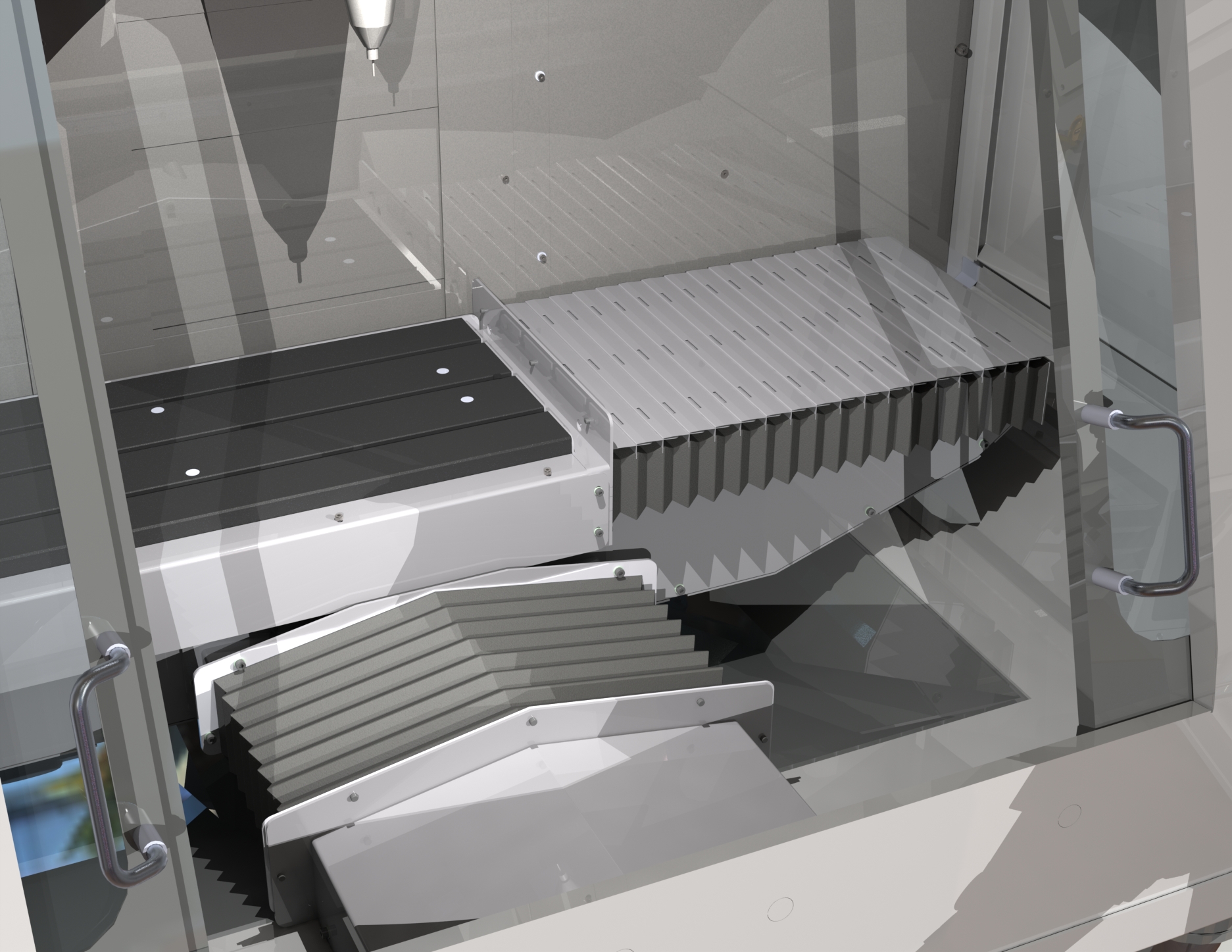

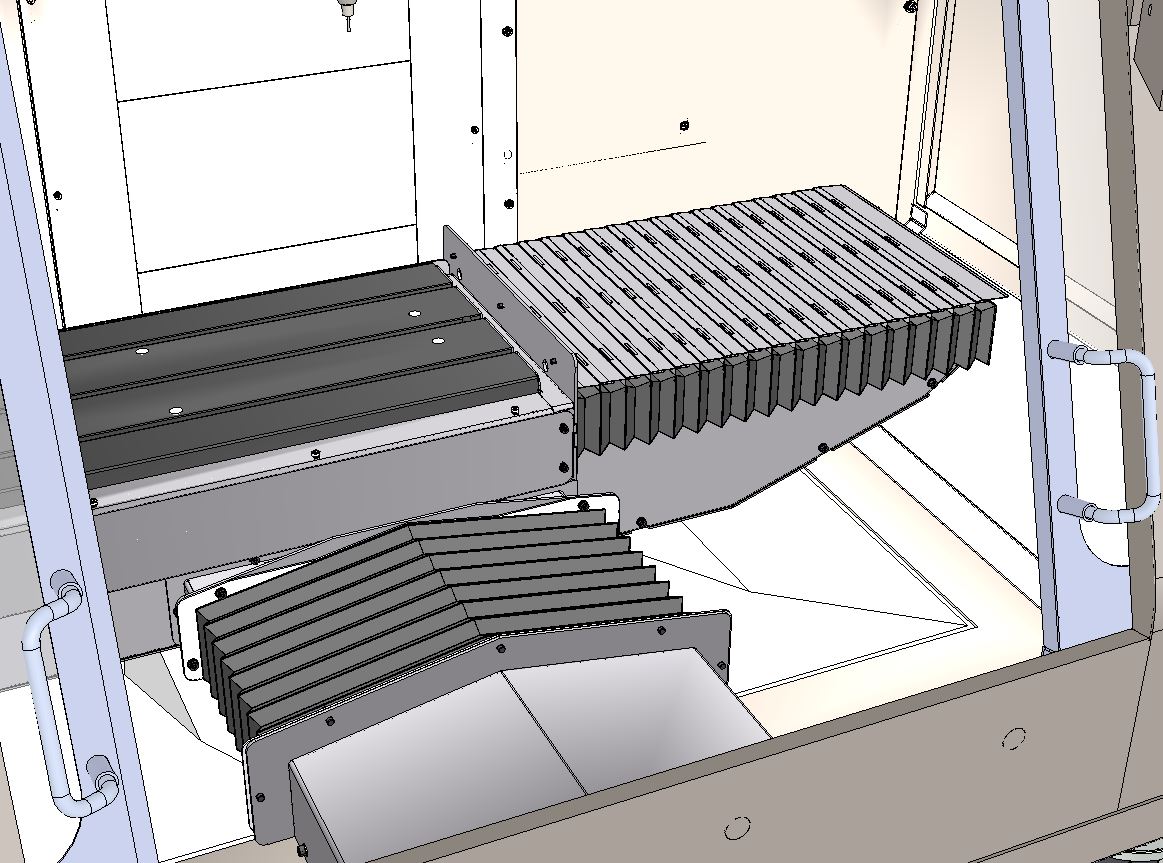

- Protection bellows :

The abrasive nature of the RV-3 ULTRASONIC machining required the installation of additional protection on the machine's casing. Bellows were therefore added to protect the machine's axis.

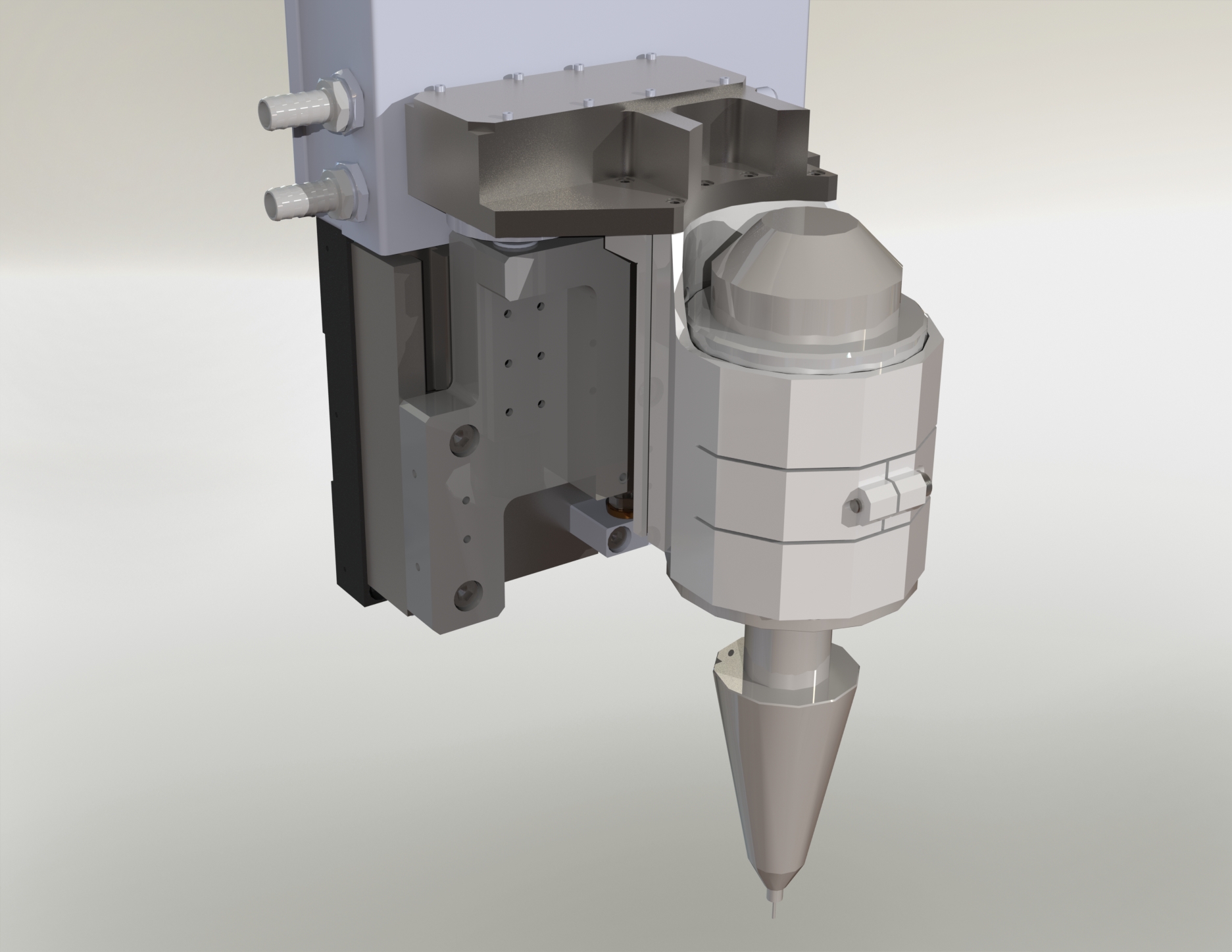

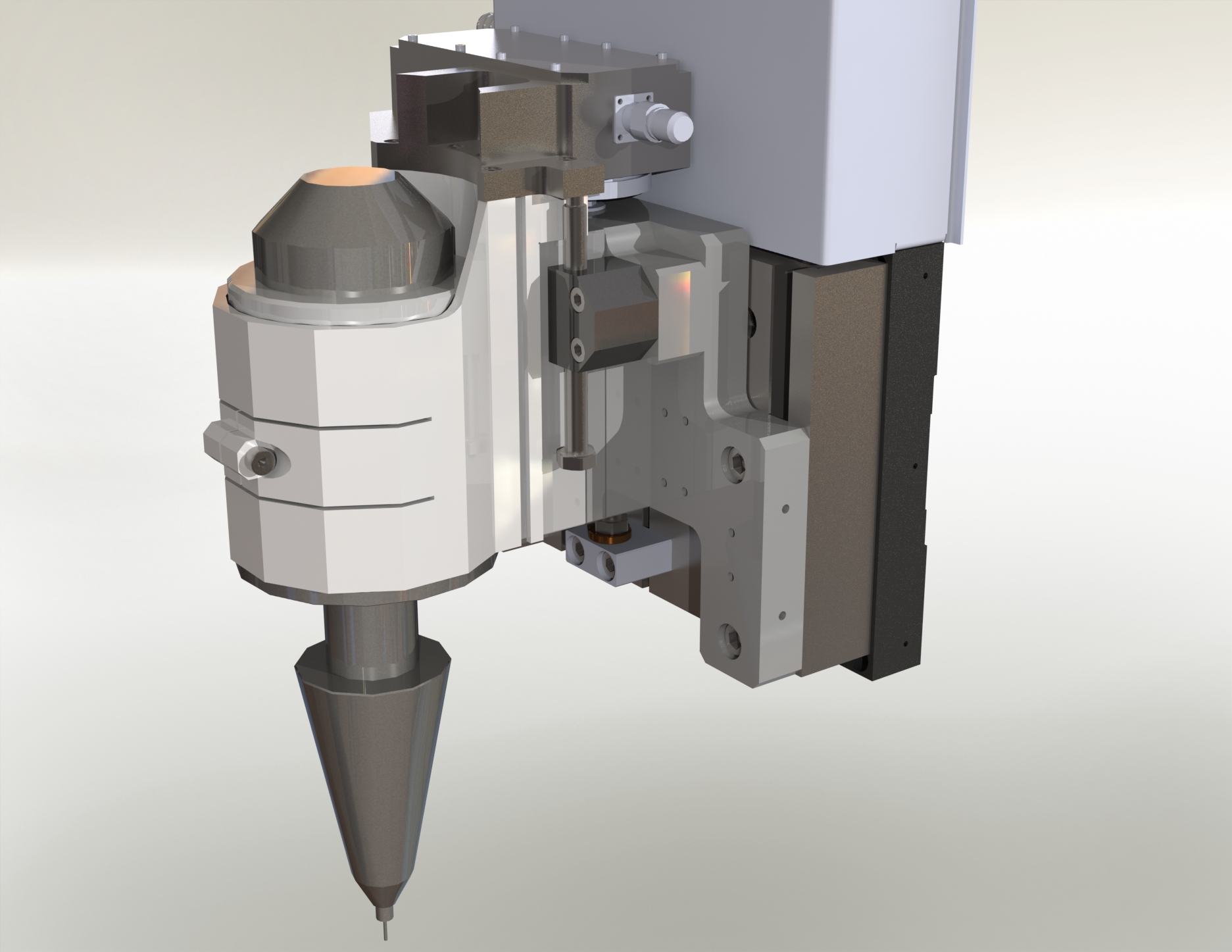

- Sonotrode :

Replacing the standard spindle, the sonotrode is the centerpiece of the RV-3 ULTRASONIC. It was created by one of our partner on this project. The sonotrode emits ultrasonic vibrations. Additional securities were implanted to remove all risks :

- Effort on the spindle head,

- Abrasive solution inside the work area,

- Overflowing.

- Effort control on the tool :

The machine is equipped with a capacitive sensor system to control the force on the tool. The sonotrode is mounted on a free rail and independent of the Z axis. In case of too high forces, this axis is released by order of the sensors thus avoiding the breakage of the tool or the part.

- Control of the abrasive liquid supply :

The abrasive liquid ensures the quality of the machining, it is then essential to control its flow. The RV-3 ULTRASONIC is equipped with an upper table on which are mounted various sensors managing the flow and level of the abrasive solution.

HEIDENHAIN 620 and integrated control screen for monitoring and adjusting the various sensors useful for the process with personalized imaging.

Conclusion

One of REALMECA speciality is being able to adapt a standard machine to a specific need. Here, starting form one of our classic machining center, we installed a custom-built ultrasonic machining system, replacing the spindle and tools by a sonotrode.