You are here

Case #5 : RM3-5 DENTAL

The machine RM3-5 DENTAL was designed by REALMECA to provide a complete solution for companies of the dental sector.

Process(es) realised :

- Scanning

- Generating a 3D file

- Assisted creation of the machining programme

- 5-axis machining

- Milling

- Turning

- Manufacturing of crowns, bridges, implants, ...

Machine(s) used :

-

Modular machining center RM3-5 DENTAL

- Milling high-speed spindle 50 000 rpm HSK-E25

- Turning spindle 6 000 rpm

- Bar capacity 12 to 18mm

- 30 or 60-station tool changer

- Workholding table with two discs

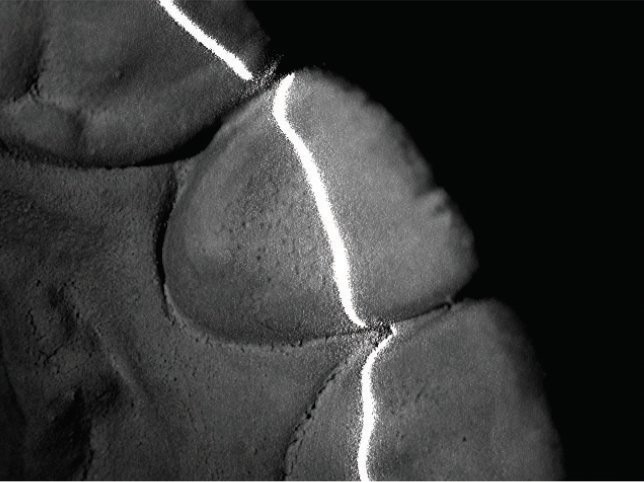

Step 1 : 3D SCANNER

- High precision 3D scanner

- 3 or 5 axis reading

- Creation of an open .STL file for printing crowns, bridges, implants, tooth, ...

- Precision : 20μm (Option 5μm)

- Scan duration : 10 to 15 minutes for 16 teeth

You can see what you are scanning. Set up the laser as needed and clic to start the scan. Once done, the scanning software gives you a .STL file saved and ready to be used in a CAD software.

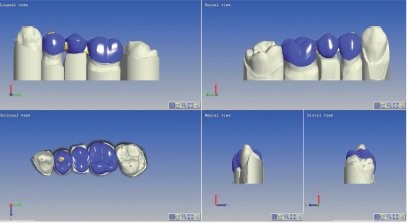

Step 2 : C.A.D.

After importing the .STL file :

- Define the anatomical parameters (cusps and pits) ;

- Define the intrados, the space for the cement, the minimum thickness of the screed, ...

- Set the contact points and spaces ;

- Test the anatomy and contact points, modify them if necessary to deform the structure until a perfect occlusal fit ;

- Change the size of the teeth or pontics, while checking for overlap.

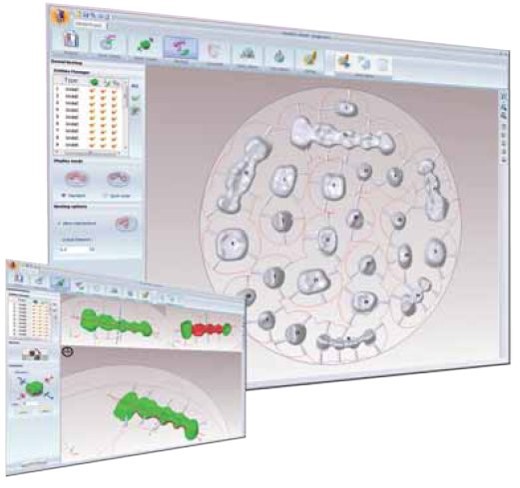

Step 3 : C.A.M.

A simple and efficient graphical interface :

The graphical interface has been specially designed for prosthetists or dental technicians who are not experts in machining :

- Assistance to guide the operator during preparations,

- Integrated interface for preparation and milling,

- Preparation and milling management.

Rapid creation of the machining project :

During this creation phase, the user has access to predefined records that will allow him to choose the key characteristics of the current project such as the material and the machine:

- Administrator or expert mode to predefine the settings,

- Operator mode for daily project creation,

- Integrated database.

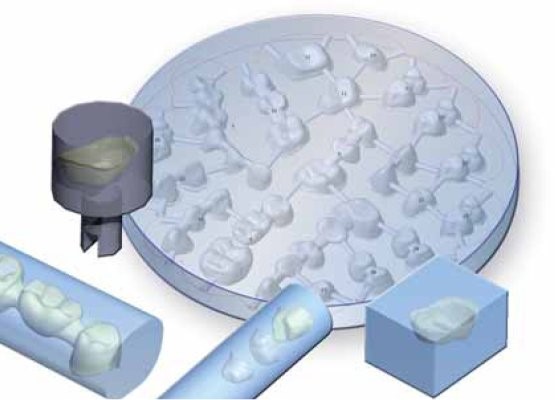

Library of supports and machining blanks :

A library of machining blanks is available. In addition to providing the classic information of dimensions or materials, the blanks can integrate meta-information that will allow to customize the machining or to take into account the shrinkage coefficients associated with certain materials such as Zircon. Custom blanks can be added to the library at any time.

- Supports or machining blanks of predefined shapes and materials,

- Creation of custom holders,

- Use of partially machined blanks

Multiple imports & automatic placement:

The import of reconstructions in .STL or native C.A.D. dental formats can be single or multiple, by simply selecting a list of files or a directory. Automatic placement frees the user from tedious tasks.

- Automatic multiple imports,

- Automatic placement,

- Interactive typing of elements to customize the machining if necessary,

- Automatic marking on the machining support (engravings on the structures or on the blank).

Optimization of orientations and placements :

A module for analyzing and optimizing orientations and placements allows you to prepare the elements for machining in the best possible way. With a simple "drag & drop" of the mouse, the elements can be nested very easily in order to limit the unoccupied zones to a maximum.

- Automatic global orientation,

- Interactive optimization by element to eliminate non-machinable areas (undercuts),

- Automatic creation of machining limit curves according to the exact morphology of the elements,

- Interactive nesting of the elements thanks to the "dynamic compass".

Automatic creation of holding and baking attachments :

- Automatic insertion of holding fixtures,

- Addition and/or modification of the position of the fasteners,

- Customization of fastener geometry according to materials,

- Library of predefined elements.

Dental machining

The generation of toolpaths is automatic. The operator does not need any machining knowledge to start this operation..

Automatic generation of toolpaths

The software has standard machining ranges adapted to the morphology of the prosthetic reconstructions in order to guarantee the best possible machining. The software is evolutive and can be enriched with new specific machining ranges by specialized engineers.

- Standard or customized machining ranges,

- Automatic choice of the best machining range according to the type of elements to be machined (screed, bridge, ...).

- Use of several different machining ranges on the same blank to guarantee the best machinability,

- Use of continuous 5-axis machining ranges if the machine allows it.

Automatic 5-axis machining

- Automatic 5-axis toolpaths without collision,

- Automatic collision avoidance according to the kinematics of the machine,

- 5-axis machine definition and custom post-processor.

Simulation and visualization of toolpaths :

- Automatic display of toolpaths on the elements to be machined,

- Dynamic machining simulations.

Communication with the machine tool :

- Parameterization of multi-machine configurations,

- Library of dental machine tool post-processors,

- Development or specific adaptation of customized post-processors,

- Machining simulations with machine kinematics.

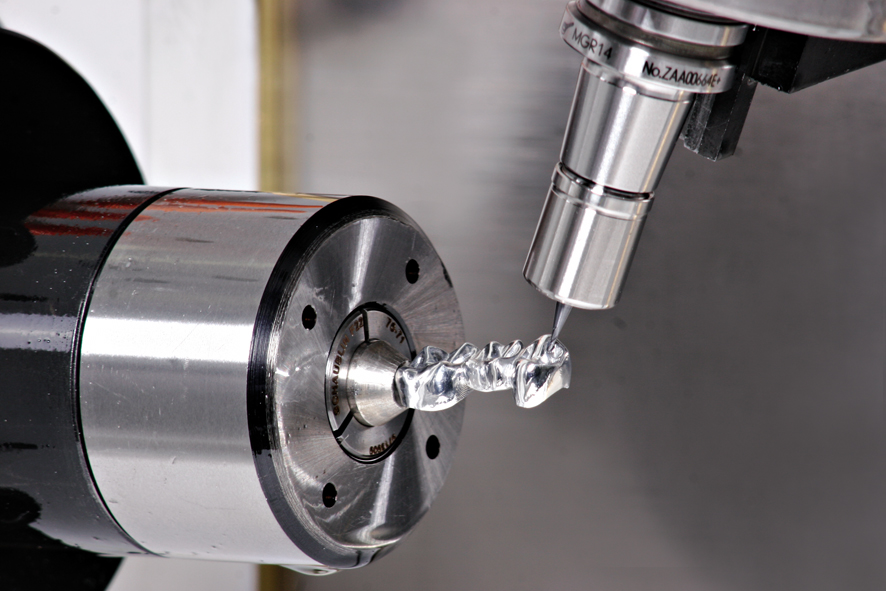

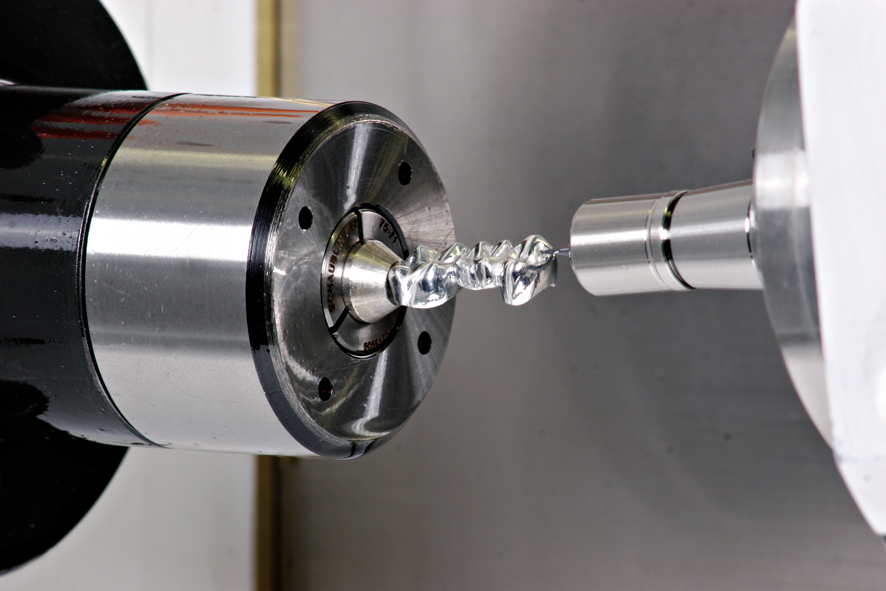

Step 4 : Machining on the RM3-5 DENTAL

Conclusion

To meet the needs of the dental sector, REALMECA has modified and adjusted one of its RM modular machine with an adapted part holder and an advanced scanning system. The whole process is facilitated, from the creation of the program to the finished part.