You are here

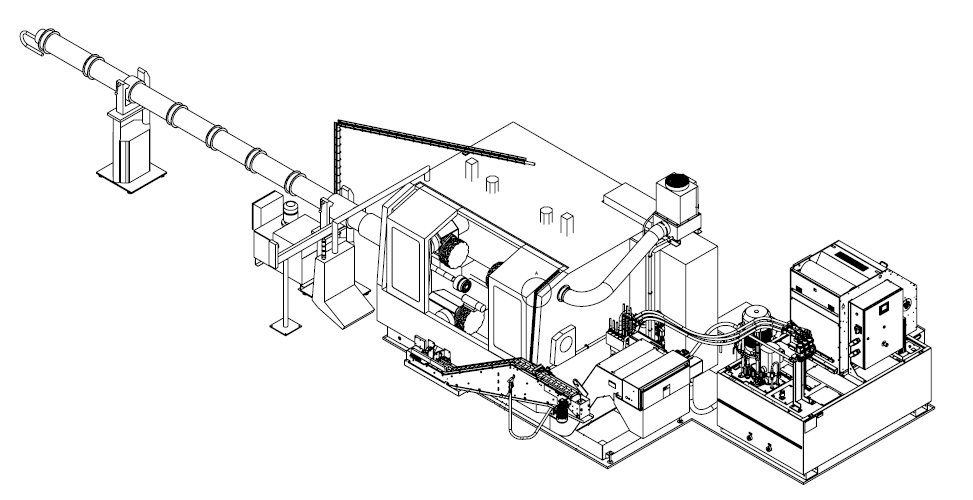

Case #2 : Production line for an automotive injection system

As part of a major export project, REALMECA has configured more than fifteen TTS Triplex, a high precision lathe made by SPINNER, to meet the needs of an international client. The goal of this project, during more than five years of collaboration, was to prepare new production site with a complete manufacturing line fine-tuned to the production of automotive parts, particularly injection systems.

Process(es) realised :

- Milling

- Turning

- Continuous multi-axis machining

- Machining with 3 turrets

- Work on the bar

- Extraction of finished parts

Machine(s) used :

-

TTS 65 TRIPLEX SPINNER

- CN SIEMENS 840D-SL

- Spindle 1, bar capacity 65mm, 5000 rpm

- Spindle 2, bar capacity 42mm, 7000 rpm

- Turret 1, 12 stations, BMT 45

- Turret 2, 12 stations, BMT 45

- Turret 3, 12 stations, BMT 45

- Part catcher

- Wireless probing system

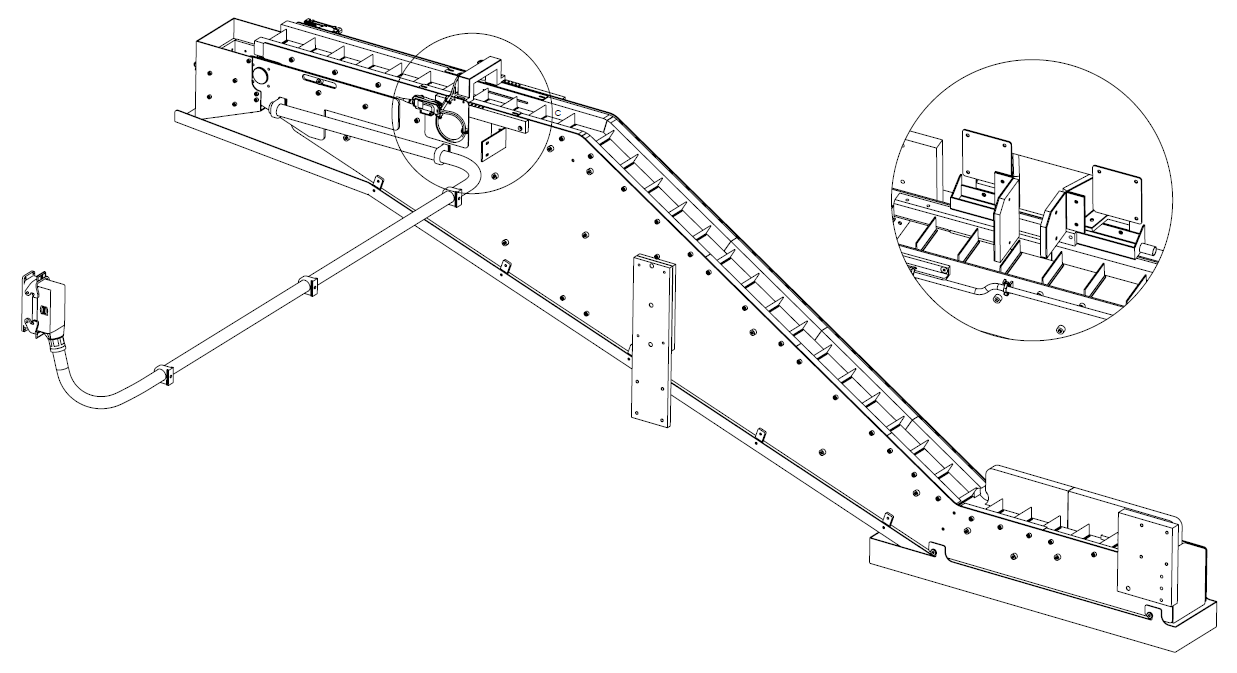

- Conveyor belt with high pressure 50bar pump

-

SHOPTURN conversational software

-

Coolant gun

- LNS barfeeder

- Conveyor belt for extracting finished parts

- Clamping devices

- Tool holders for live and fixed tools

- POKA YOKE camera

- Writing of machining programs

- Chip collection box

- Training for the use and maintenance

Conclusion

Today, more than 15 machines have been installed in these factories. The maintenance is managed by the service team of REALMECA and its engineers. Either, through phone calls and emails or by sending our technicians directly in the client's workshops.